Our Products

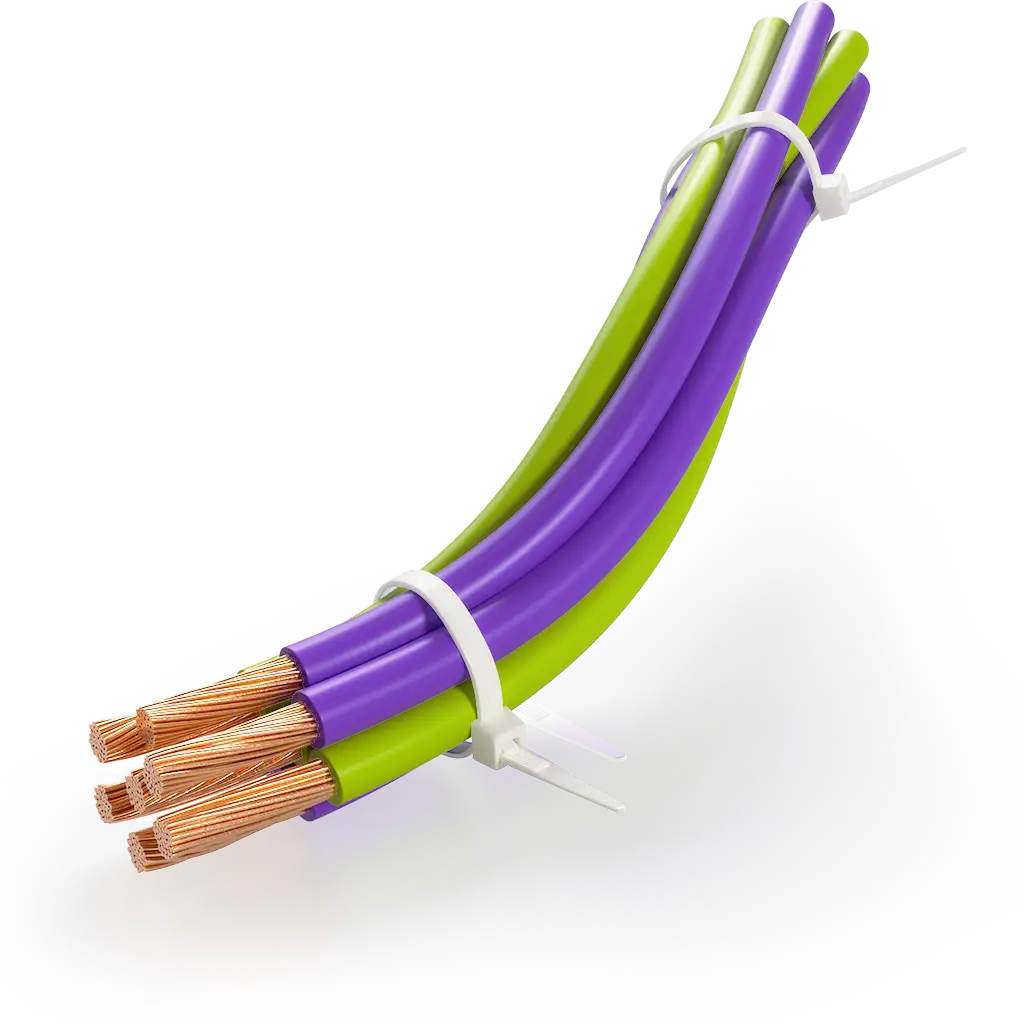

Cable ties

Ziplex branded cable ties are the multipurpose fastenings and are made from polyamide 6.6 or nylon, which has high strength properties. Nylon cable ties are used for fixing and laying wires and cables during repair, installation and construction works in industry, communications, construction and utilities field.

Usage

Electrical installation work

Cable ties are used for arranging and banding cables and wires, marking and fixing cables during the installation of electrical wiring and structured cabling systems. They are often used for wiring at various events and exhibitions.

Construction

Cable ties are used for creating flexible connections (PVC pipes, HDPE pipes, etc.), assembling structures, and laying network systems.

Storage facilities

Cable ties are often used at warehousing space arrangements, installation of shelving units and show-cases. They are also used for labeling (fixing tags, price tags, labels), packing and packaging of products.

Everyday tasks

Cable ties are perfect for everyday tasks. They provide an endless number of fastening solutions at home, in the garden, at the job site, the next camping trip and everywhere in between.

Characteristics

Cable ties characteristics

Ziplex branded plastic cable ties are produced from polyamide-6.6 (PA) or nylon, which retains its mechanical properties at high and low temperatures, is self-extinguishing and resistant to self-ignition. It is also resistant to the damaging effects of mold and bacteria, as well as fuels and lubricants. Cable ties are available in a variety of colors: from white (unpainted) and black (UV resistant) to red, green and yellow, making them virtually invisible if necessary.

Material Nylon PA 6.6.

Ultraviolet resistant material.

Oils resistant material.

Non-flammable self-extinguishing material.

Material with good chemical resistance.

Available in a range of colors.

Specification

Specification

| SKU | Dimensions, (mm) | Colors | Ø max. bundle (mm) |

Max. tensile strength, (kg) | Qty. per pack (pcs) |

|---|---|---|---|---|---|

| CT1 0310x | 3x100 | white (natural), black, green, blue, red, yellow | 20 | 10 | 100 |

| CT1 0315x | 3x150 | white (natural), black, green, blue, red, yellow | 38 | 10 | 100 |

| CT1 0320x | 3x100 | white (natural), black, green, blue, red, yellow | 52 | 10 | 100 |

| CT1 0415x | 4x150 | white (natural), black, green, blue, red, yellow | 38 | 18 | 100 |

| CT1 0420x | 4x200 | white (natural), black, green, blue, red, yellow | 52 | 18 | 100 |

| CT1 0425x | 4x250 | white (natural), black, green, blue, red, yellow | 72 | 18 | 100 |

| CT1 0430x | 4x300 | white (natural), black, green, blue, red, yellow | 85 | 18 | 100 |

| CT1 0437x | 4x370 | white (natural), black, green, blue, red, yellow | 107 | 18 | 100 |

| CT1 0520x | 5x200 | white (natural), black, green, blue, red, yellow | 52 | 25 | 100 |

| CT1 0525x | 5x250 | white (natural), black, green, blue, red, yellow | 72 | 25 | 100 |

| CT1 0530x | 5x300 | white (natural), black, green, blue, red, yellow | 85 | 25 | 100 |

| CT1 0535x | 5x350 | white (natural), black, green, blue, red, yellow | 101 | 25 | 100 |

| CT1 0540x | 5x400 | white (natural), black, green, blue, red, yellow | 115 | 25 | 100 |

| CT1 0830x | 8x300 | white (natural), black, green, blue, red, yellow | 85 | 41 | 100 |

| CT1 0840x | 8x400 | white (natural), black, green, blue, red, yellow | 115 | 41 | 100 |

| CT1 0850x | 8x500 | white (natural), black, green, blue, red, yellow | 145 | 41 | 100 |